Venturi-Effect Powder & Fibre Pneumatic Dosing Unit

Design Brief & Constraints

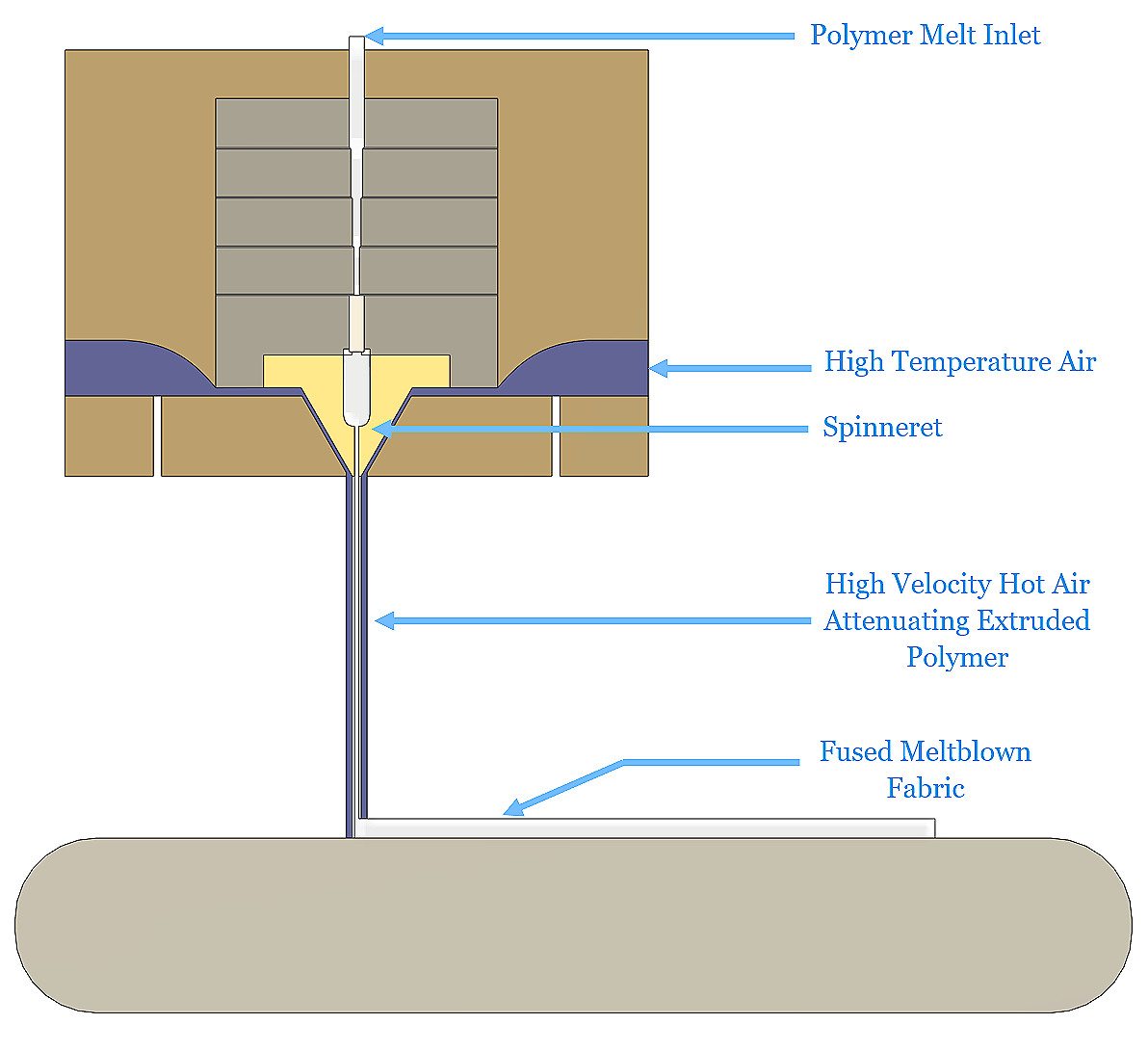

The uniqueness of nonwoven fabric structures lies in its name. Unlike traditional textiles, which require weaving or looping yarns to form a fabric, nonwovens rely on chemical adhesion, mechanical entanglement, or thermal fusion to form a bonded fibrous structure. With the latter, specific processes can form fabrics straight from polymer beads using a process called ‘Meltblown’. Here, the polymer is melt extruded directly into high-velocity, high-temperature air streams and collected onto a belt former; the process relies on the polymer being heated above its latent heat of fusion during impact with the belt, resulting in a self-bonded fabric.

An emerging technological innovation is ‘coforming’. This is a process used alongside meltblown to add functionality to the fabrics with powders and/or fibres that improve the properties of the constituent polymer.

The objective of the project, at face value, can be put simply as designing and producing a piece of equipment that allows coforming to be carried out in conjunction with meltblowing, using either powders or fibres. From this, the following design constraints were decided upon:

Capability to deliver both mediums of powder and fibre to the ejected polymer stream before impact with the conveyor

Must spread the delivered medium over the full 30 cm width of the

Economical form: it must fit within the immediate footprint of the meltblown lines’ spinning zone

Must withstand temperatures between to 35 and 40 degrees Celsius without deformation

Initial Ideation

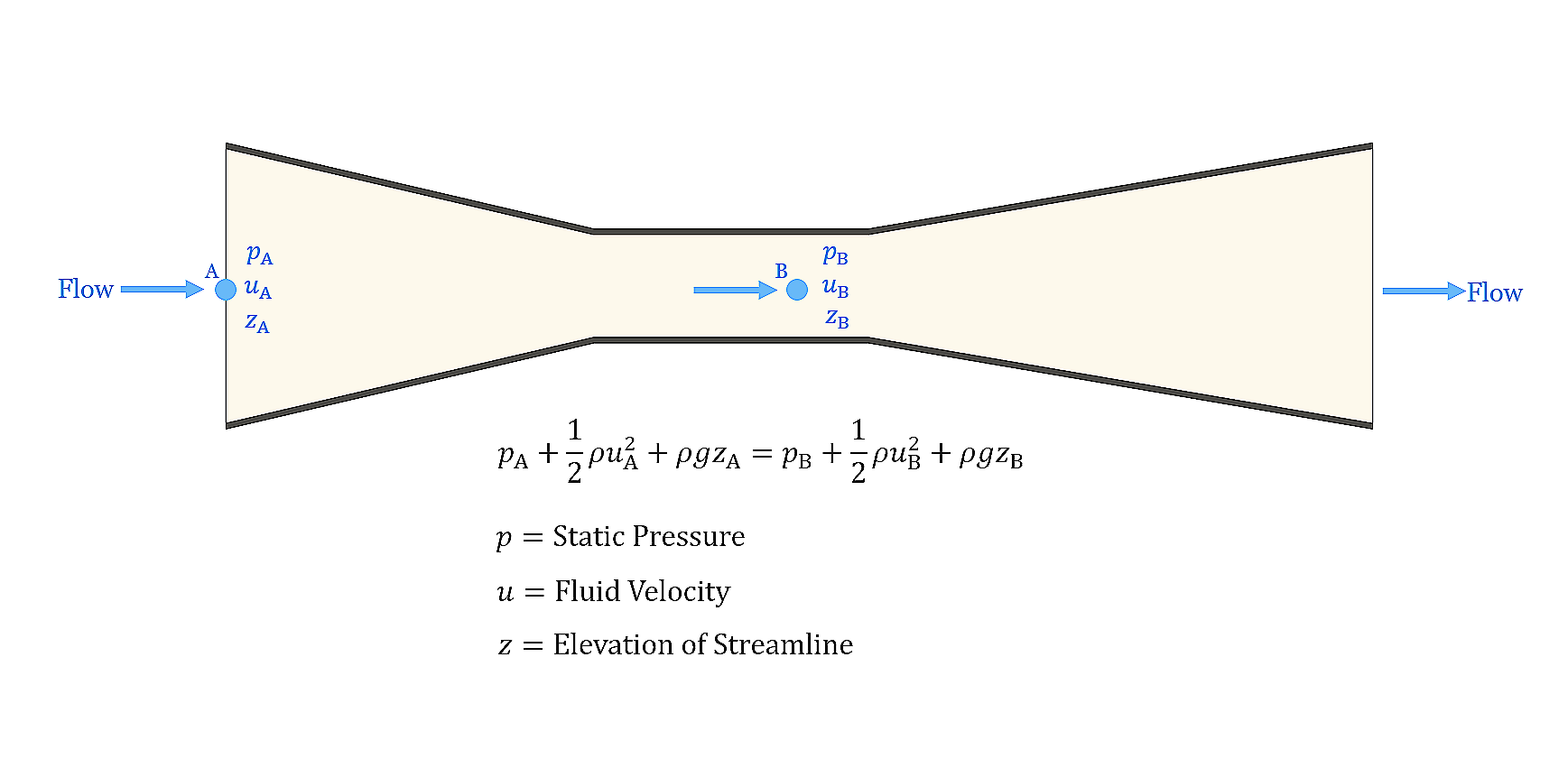

Initially, ideation centred on ways to manipulate the Bernoulli principle. This is a famous principle in physics that describes the conservation of energy in incompressible fluid flow. The principle states that along a streamline of fluid, the sum of the pressures at any two points along the streamline must be equivalent. The following equation describes this:

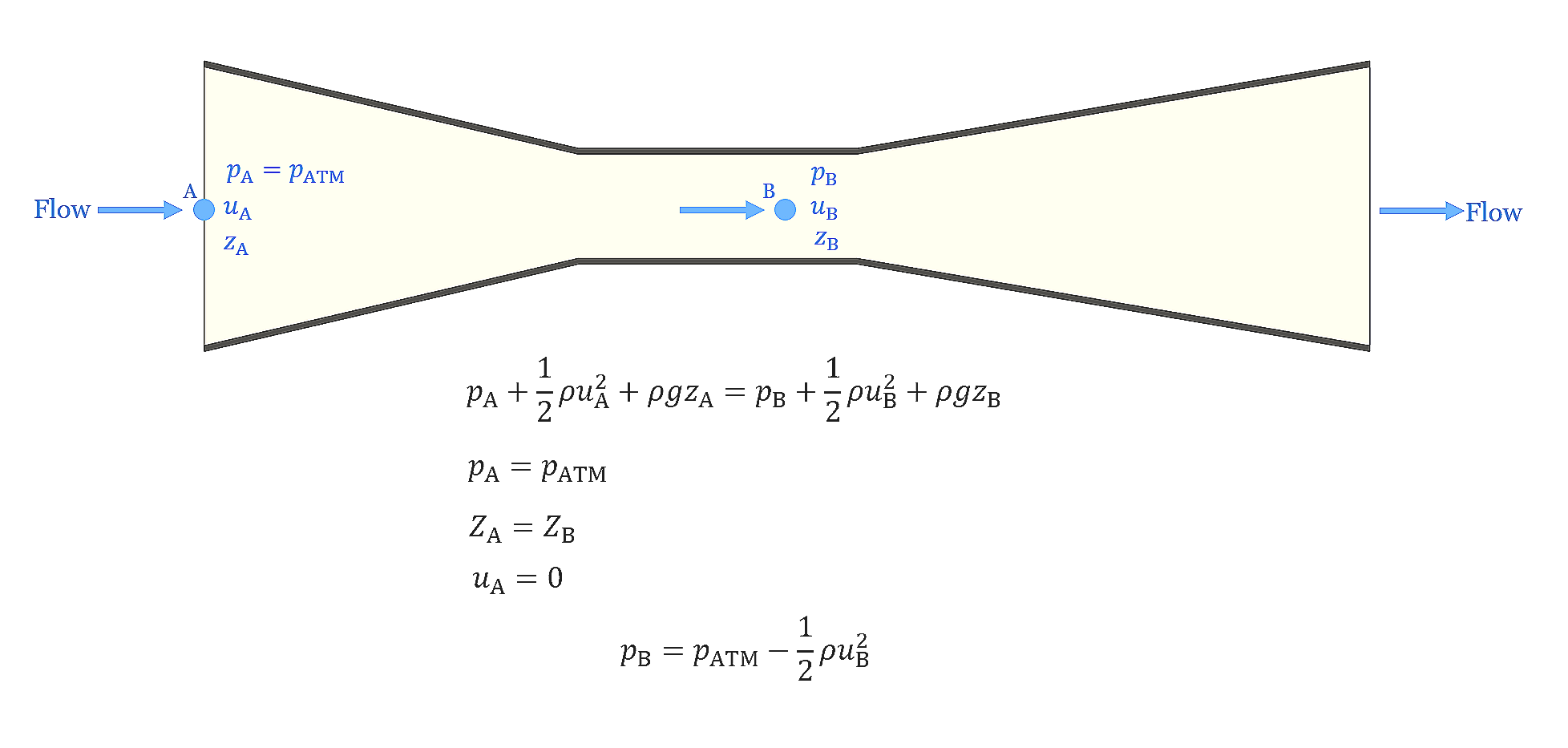

Italian physicist Giovanni Venturi realised that this gave rise to interesting behaviours when the geometry enclosing the fluid was varied. It was discovered that if an incompressible fluid were forced through a constriction, it would accelerate to a higher velocity as the static pressure in the constriction decreased. If we take the example from the above diagram, this results in a pressure drop below atmospheric pressure:

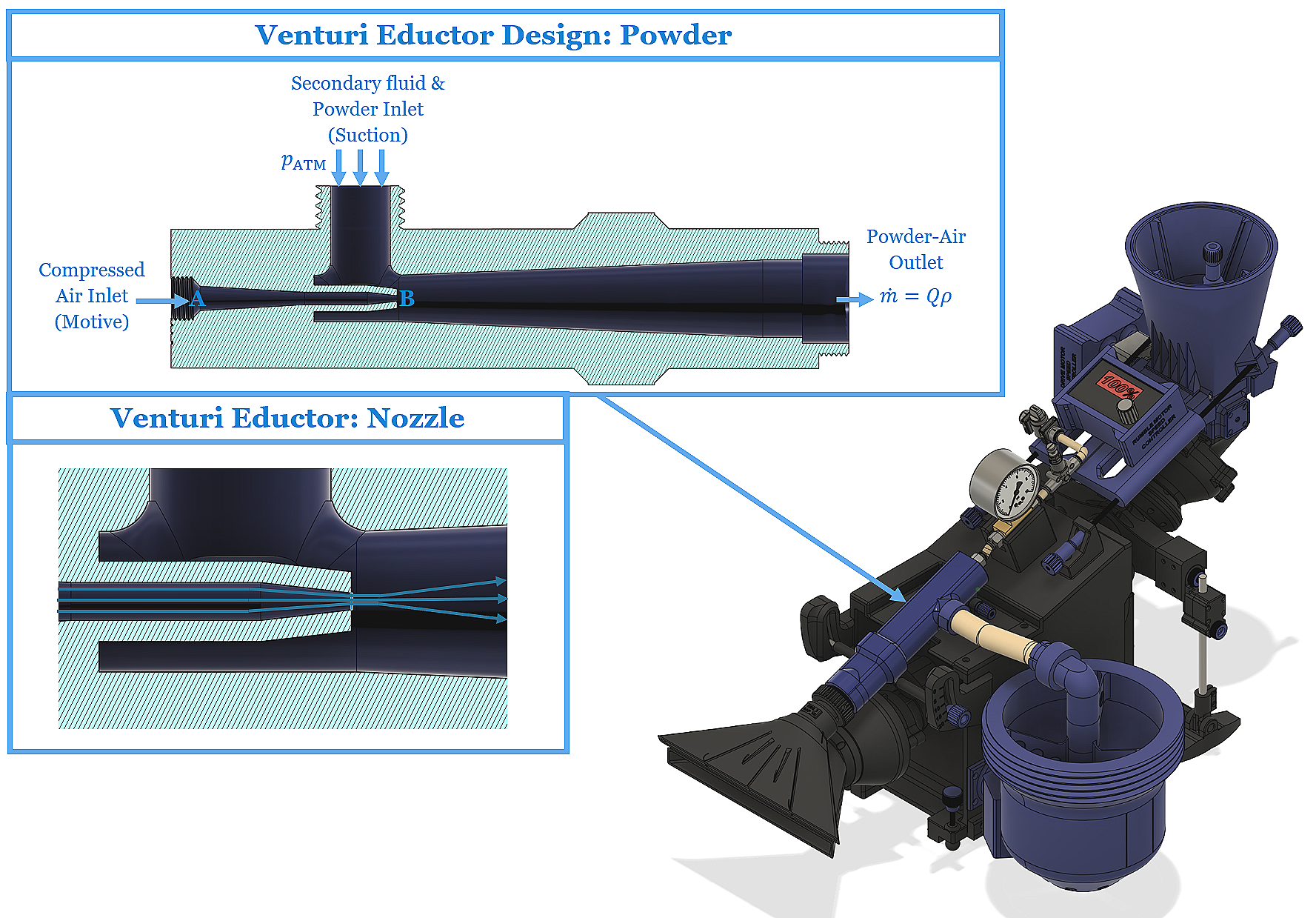

Initial research uncovered air pumps, called Venturi-eductors, utilise the Venturi effect. They offer several benefits over mechanical pumps, thanks to their simplicity and lack of moving parts. This becomes the focal point for the project's pumping system of both the powder and fibre.

Design Concept

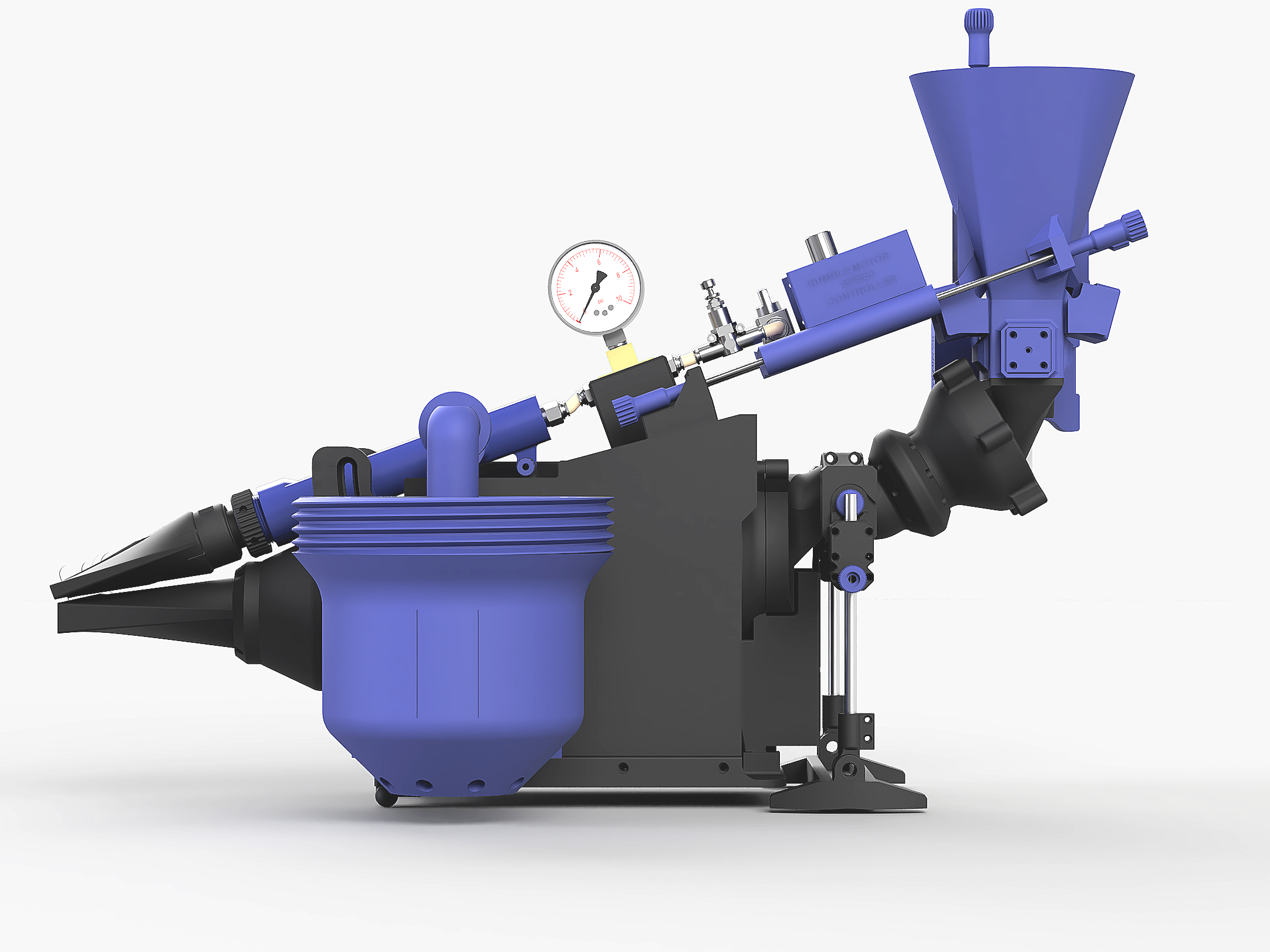

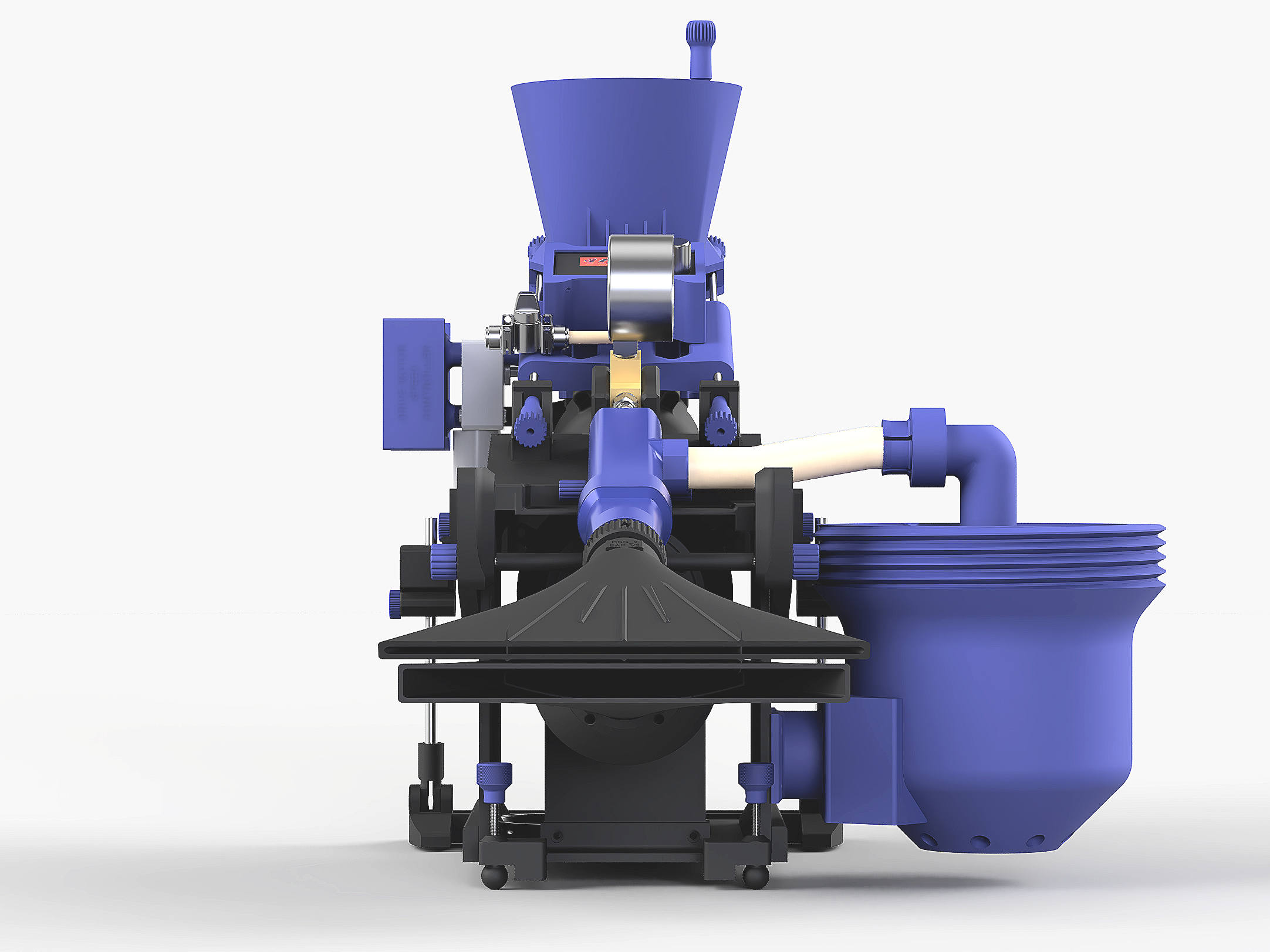

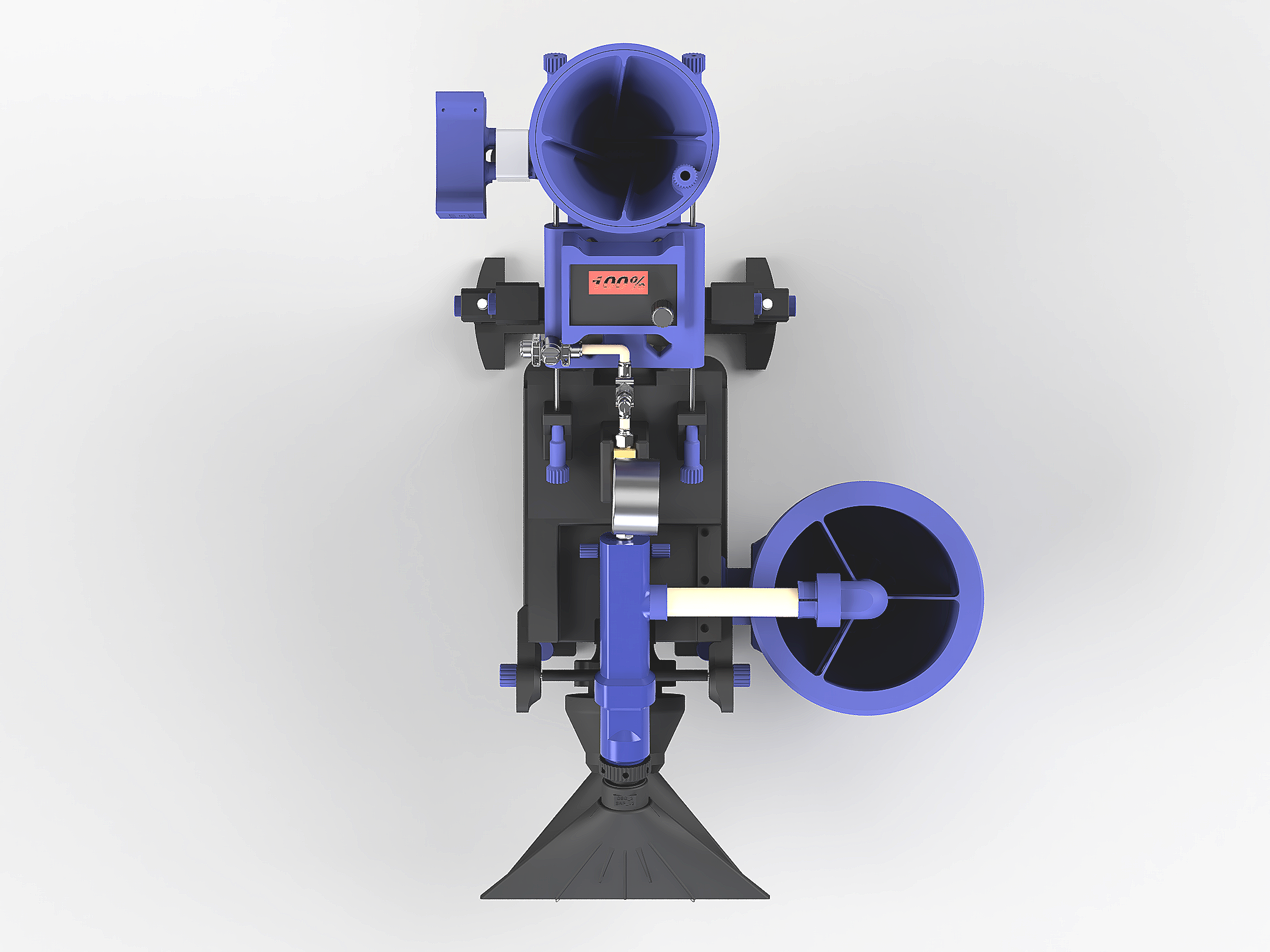

The concept relies on manipulating this effect to create a vacuum system that draws particles and fibres into the meltblown polymer stream. The solution comprises two Venturi units in parallel: one for powder particulates and the other for fibres. The designs of which differ to deal with the dissimilarity in aspect ratios between powders and fibres. The key features of the design include:

Two independent Venturi eductors for conveying both powders and fibres

Two spreading nozzles after each eductor to evenly spread the powder and fibre over the width of the meltblown fabric

A suction-driven powder hopper and suction-aided metered fibre hopper

Fibre separation chamber to reduce clumping post hopper and pre spreading nozzle

Concept Features: In-Depth

Powder: Venturi-Eductor

Principle

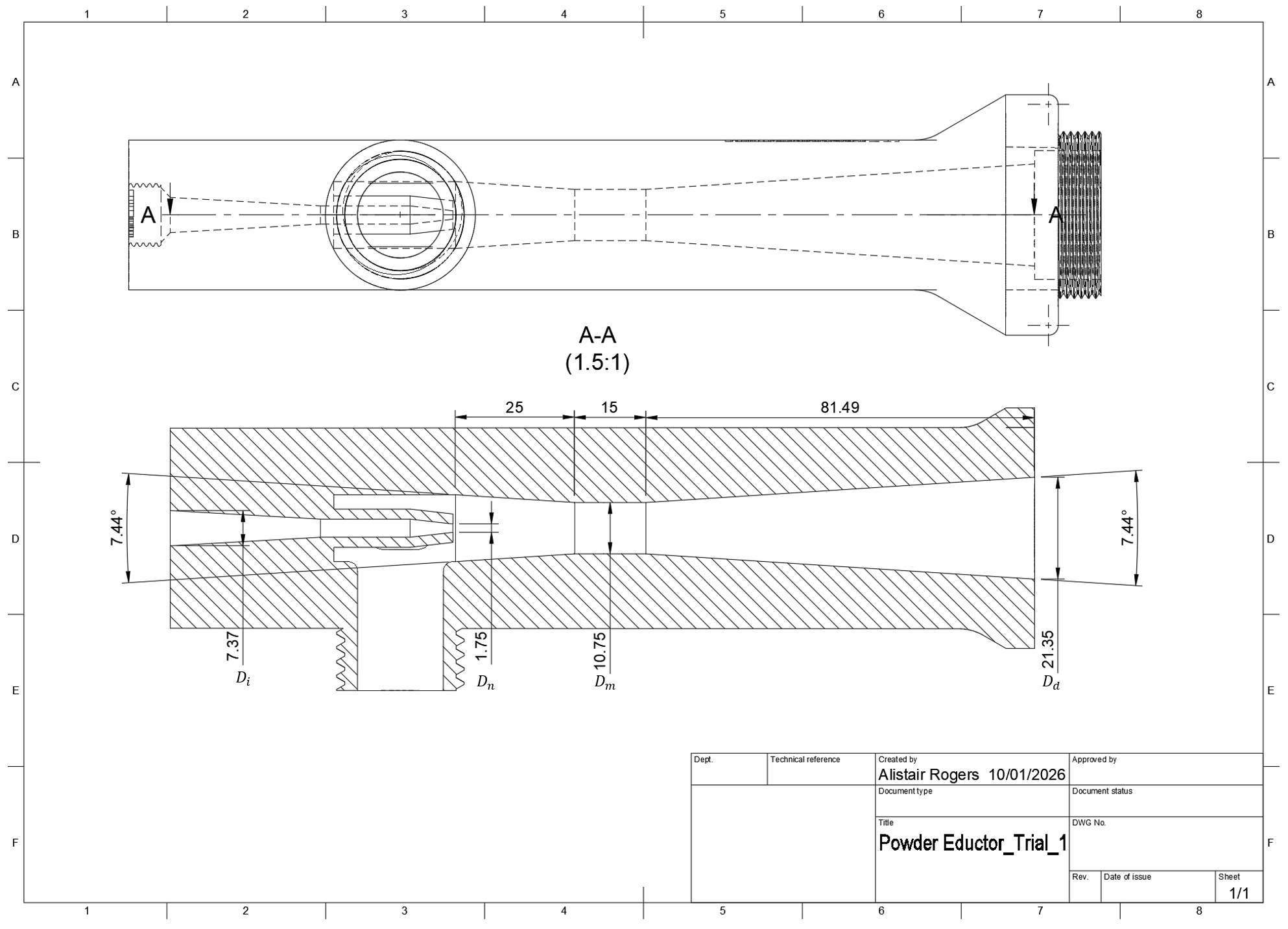

The eductor is designed to utilise the venturi-effect previously discussed. High-pressure motive air is introduced into a converging nozzle at point ‘A’ in the above figure, which accelerates the motive fluid, converting pressure energy into kinetic energy by increasing its velocity at point ‘B’. A secondary inlet, at atmospheric pressure, perpendicular to the motive air flow, becomes a suction port due to the motive fluid expanding and reducing below atmospheric pressure. As momentum is transferred between the low-pressure motive fluid and the secondary higher-pressure suction fluid (containing the solid particles) the dilute secondary fluid is entrained and mixed with the motive fluid and discharged from the outlet.

Design Requirements

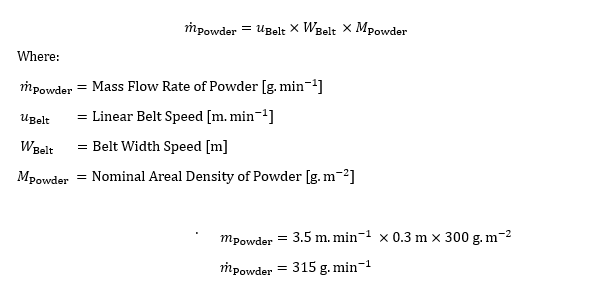

The coform prototyping platform was required to provide >300 g of fibre per metre squared of fabric (300 g.m-2). The metlblown equipment has an effective faqbric width of 30 cm and nominally runs at 3.5 metres per minute. Therefore, we can calculate the minimum required mass throughput needed for the powder as follows, in grams per minute:

Design Proposal

Although access to specialist CFD software was not available to the author during this project, certain critical geometric parameters are known to affect the performance of the powder eductor, based on the author's knowledge. These geometric parameters are as follows:

Nozzle Diameter-to-Inlet Diameter Ratio (Di/Dn): This will determine how effectively the pressure energy is converted into kinetic energy, i.e. how much the motive fluid accelerates, impacting the momentum transfer and expansion of the jet in the mixing chamber. Having a nozzle that’s too fine may constrain mass flow without increasing gains in suction

Mixing Diameter (Dm): The mixing diameter is essential in ensuring there is enough volume for the required entrainment to mix effectively without the eductor clogging, leading to flow reduction and reduced conveyance

Diffuser Diameter (Dd) and total length of mixing/diffusion length: These parameters will determine the static pressure increase of the solid-air phase as it exits the eductor and into the spreading nozzle. If the pressure is too high, this will negatively impact the formation of the perpendicular meltblown filament stream; if it is too low, the ejected powder stream may sediment in the spreading nozzle.

A technical drawing presenting the geometry of the powder eductor is presented below. When the eductor is combined with the spreading nozzle, the true powder discharge rate can be determined through experiment with a given powder.

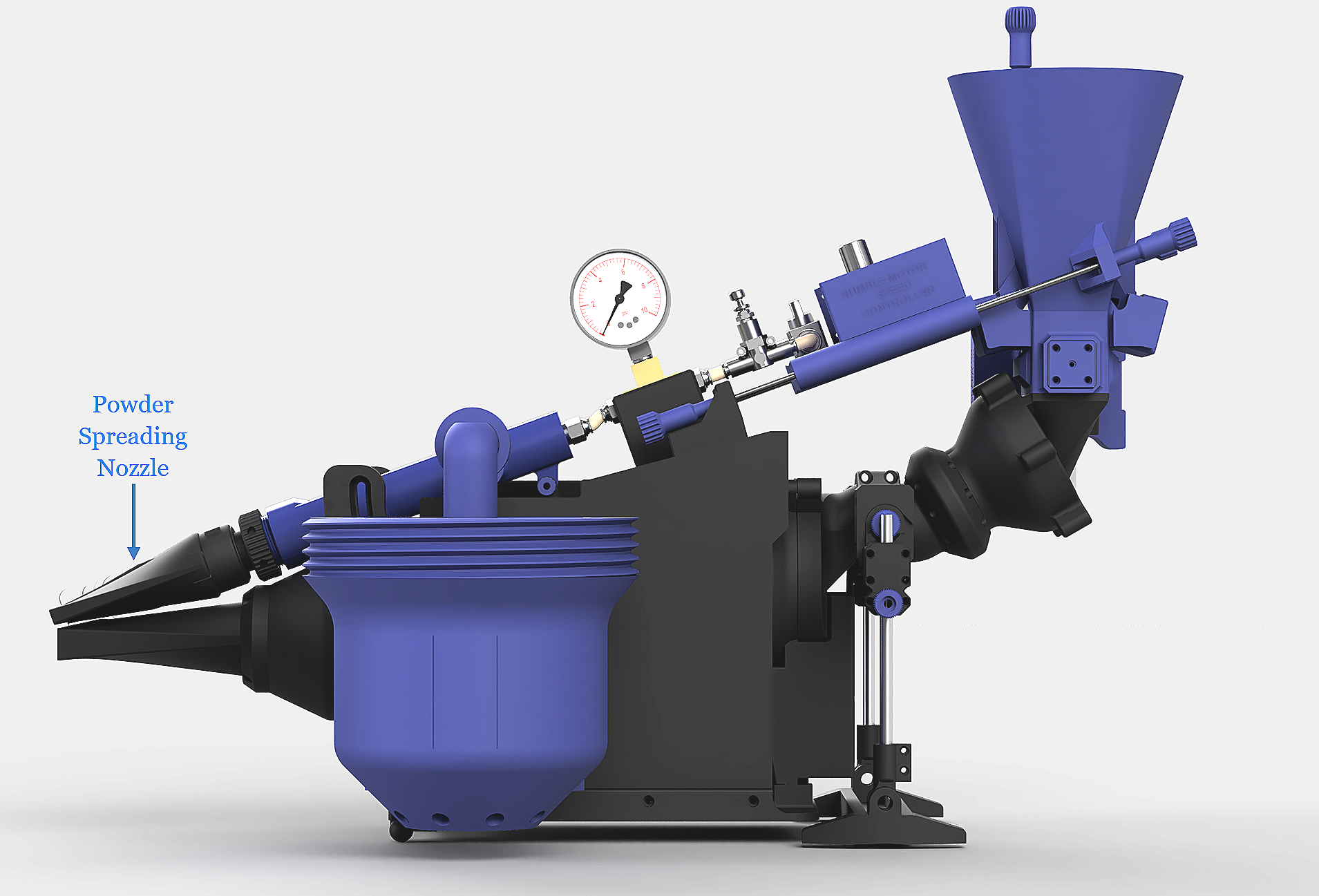

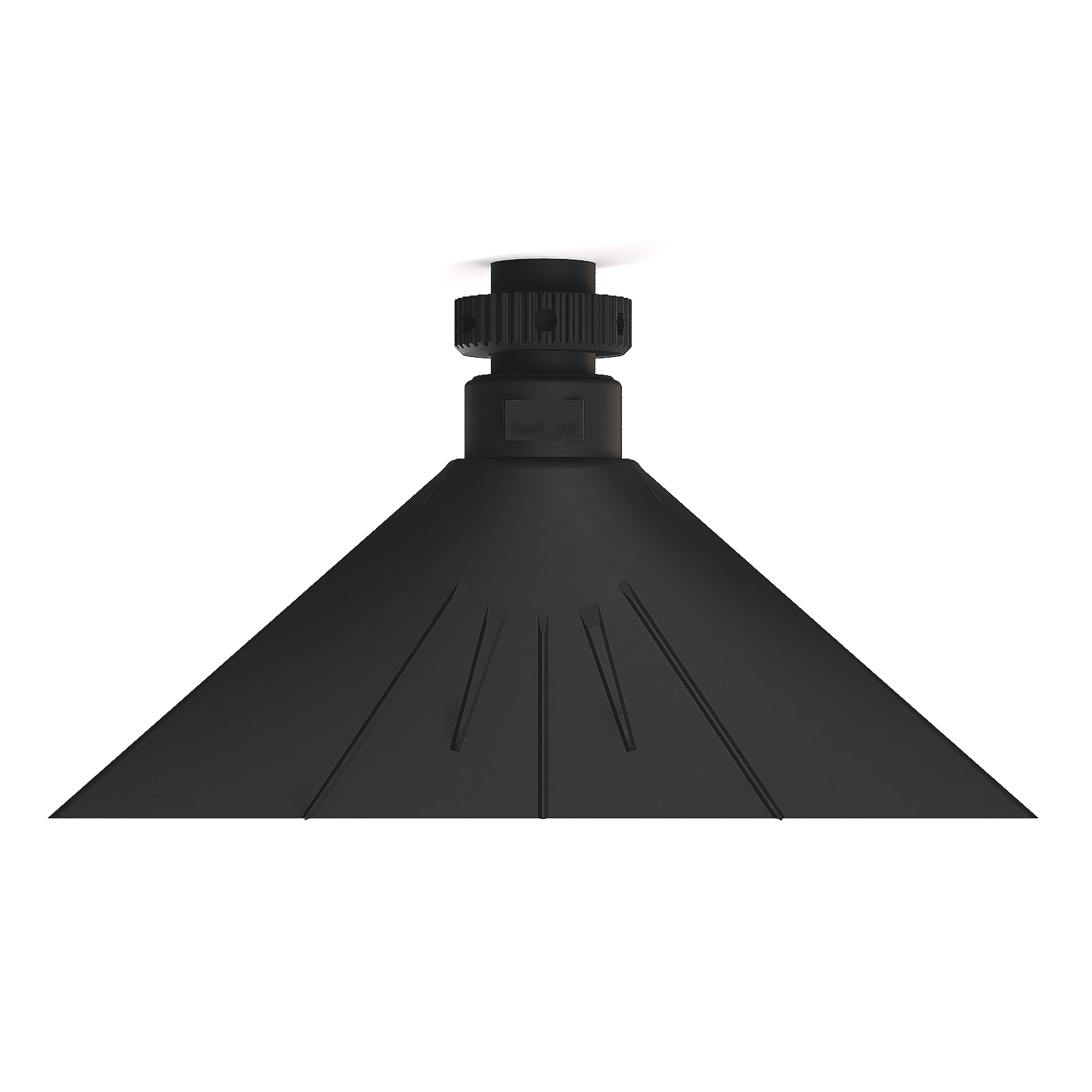

Powder: Spreading Nozzle

Design Proposal

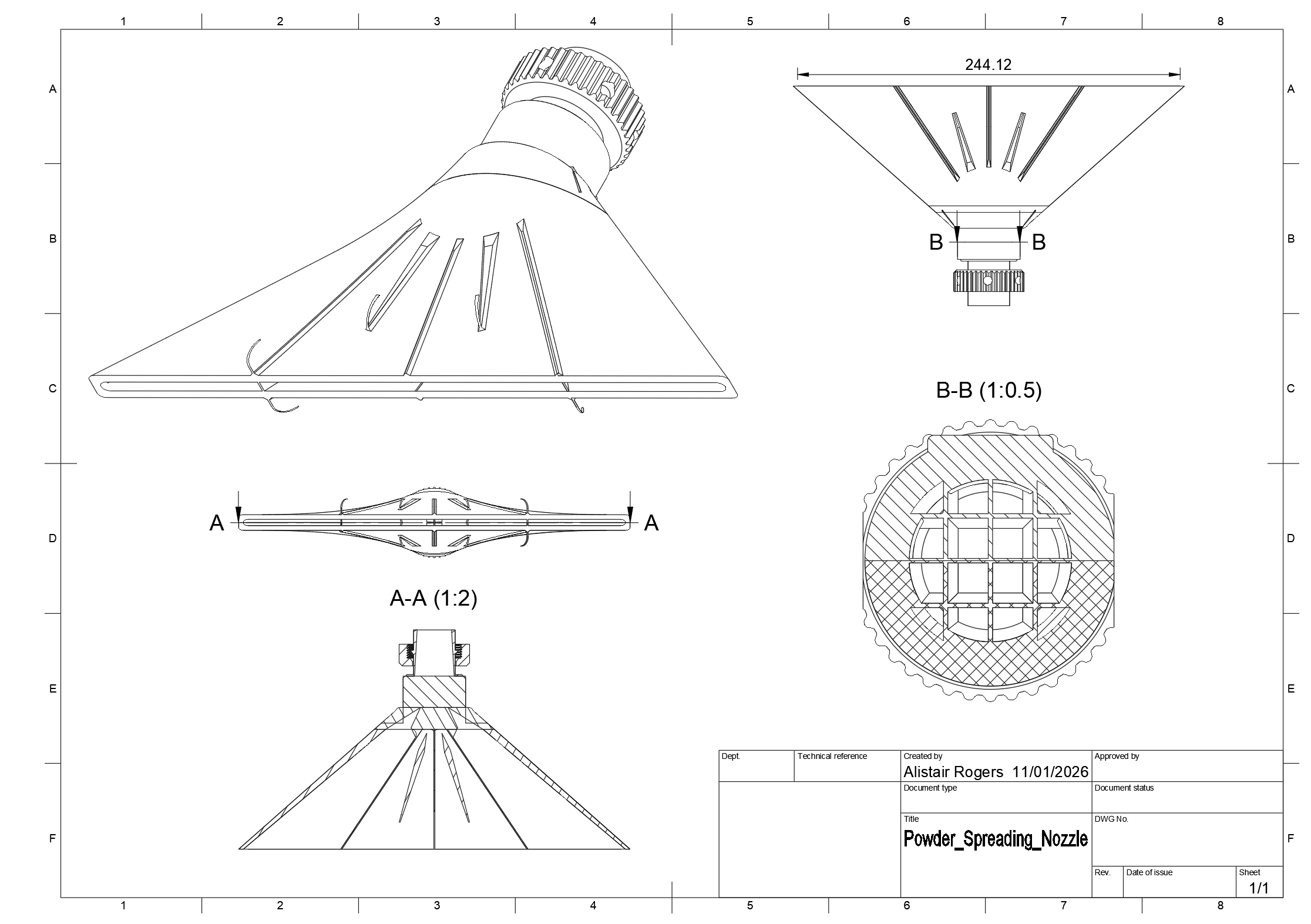

As the air-powder mixture is ejected from the diffuser outlet of the powder eductor, it is integral to the uniformity of the coforming process that it be spread evenly over the 30 cm fabric width. It was theorised that as the mixture entered a diverging nozzle, which increased in width as a function of its length, the mixture would not spread out evenly to the required width and there would be a bias towards the centre of the nozzle. To prevent this and motivate a more even distribution, an internal channel system was integrated within the nozzle. This gradually diverged outward across the nozzle width with aim of providing guided laminar flow pathways for the powder-air mix.

Powder: Hopper

Design Proposal

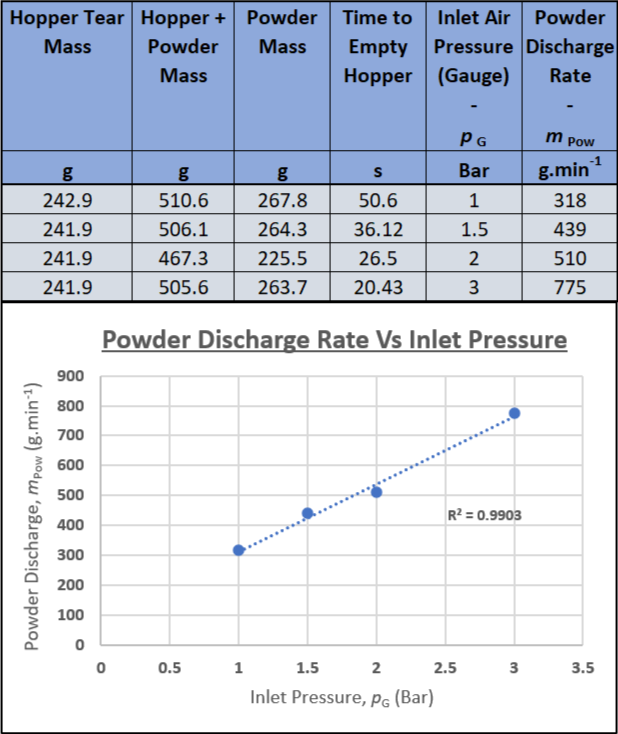

Experimental Validation: Powder Eductor, Nozzle and Hopper

Experiments were carried out on the powder eductor to determine the powder discharge rate as a function of inlet gauge pressure. The experiment was configured as follows;